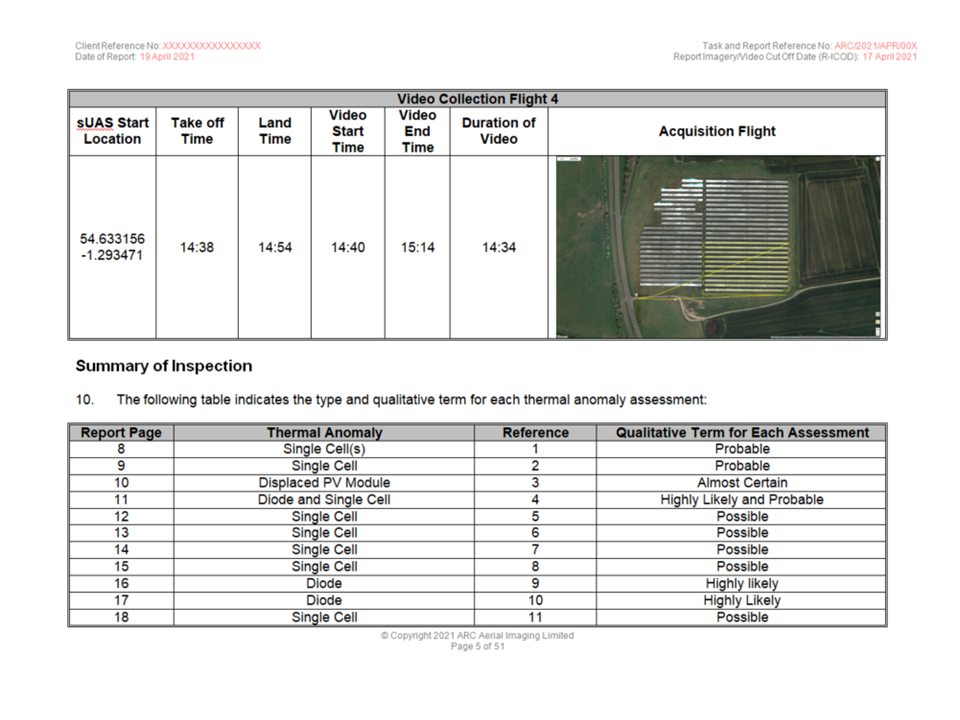

THERMAL INFRARED AERIAL INSPECTIONS.

Reduce the cost of solar Thermal infrared inspections by 40% and the time by 80%!

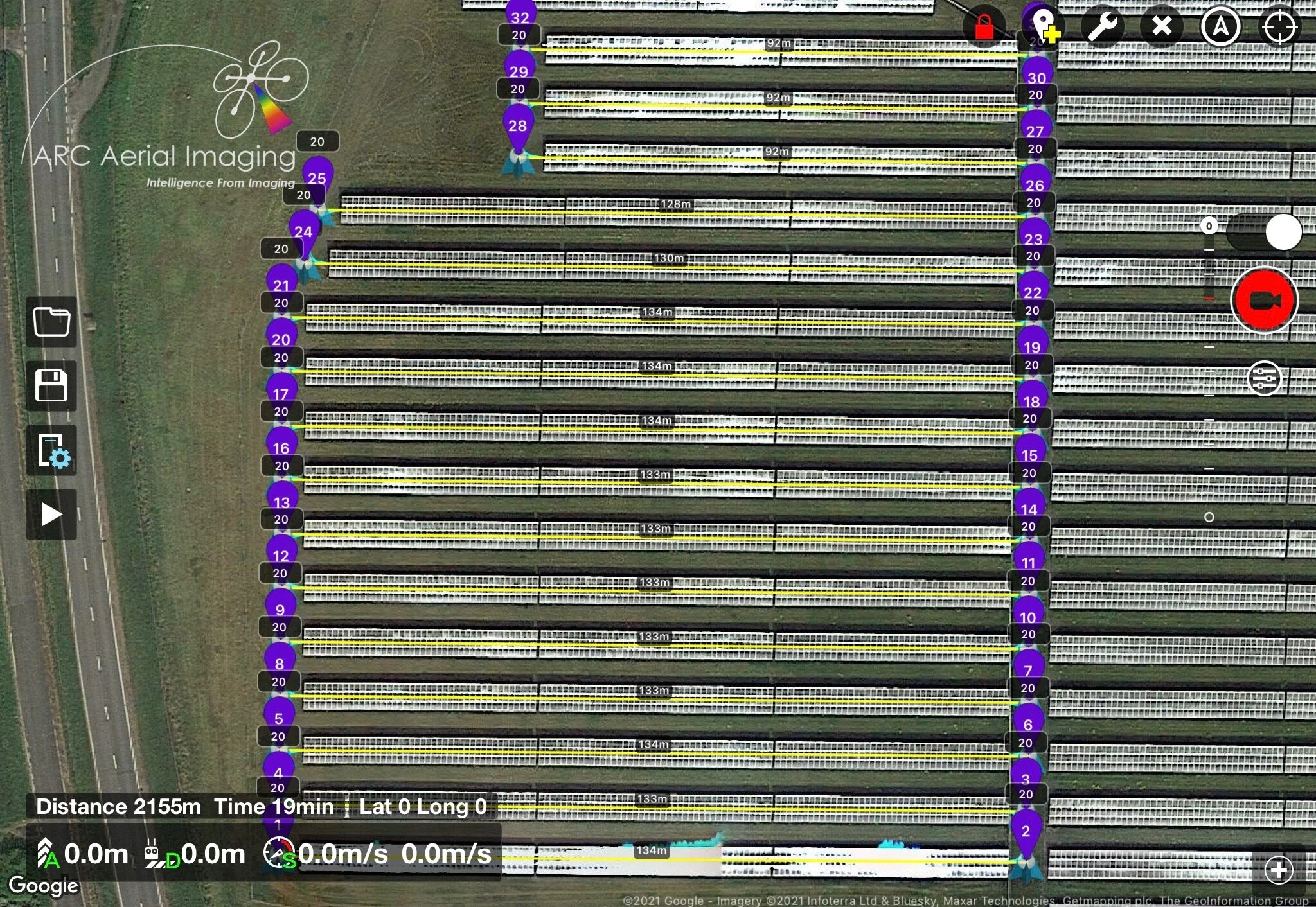

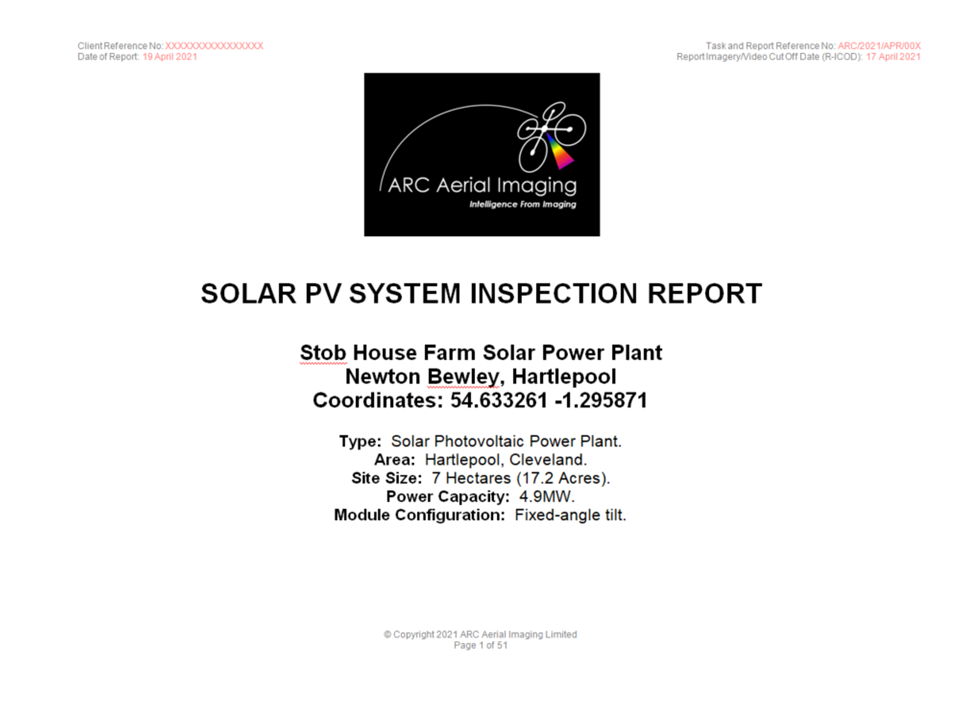

ARC Aerial Imaging’s goal is to improve the operational performance, efficiency and safety of your solar facility and we use advanced drone technology, infrared and high-resolution visual cameras with autonomous flight planning software to accurately collate and provide thermal and visible aerial imaging to provide actionable information to increase site operational performance, efficiency and safety.

Our highly-experienced operator will coordinate with the client to accurately plan and conduct both stills and video outputs of your solar infrastructure required as part of its routine maintenance and preventative . We’ll use our extensive planning knowledge and acquisition experience with our drone imaging technology to autonomously collate accurate, high-quality, reliable data for that solar-related inspection requirement.

Aerial thermography (infrared) can detect faults in photovoltaic (PV) systems that cannot be ascertained using traditional visible methods. By using drones and thermographic images to classify the component and reveal the exact location of PV anomalies will improve overall PV system inspections by reducing costs, inspection time, reduce hazardous risk to personnel and improve the site’s operational efficiency.

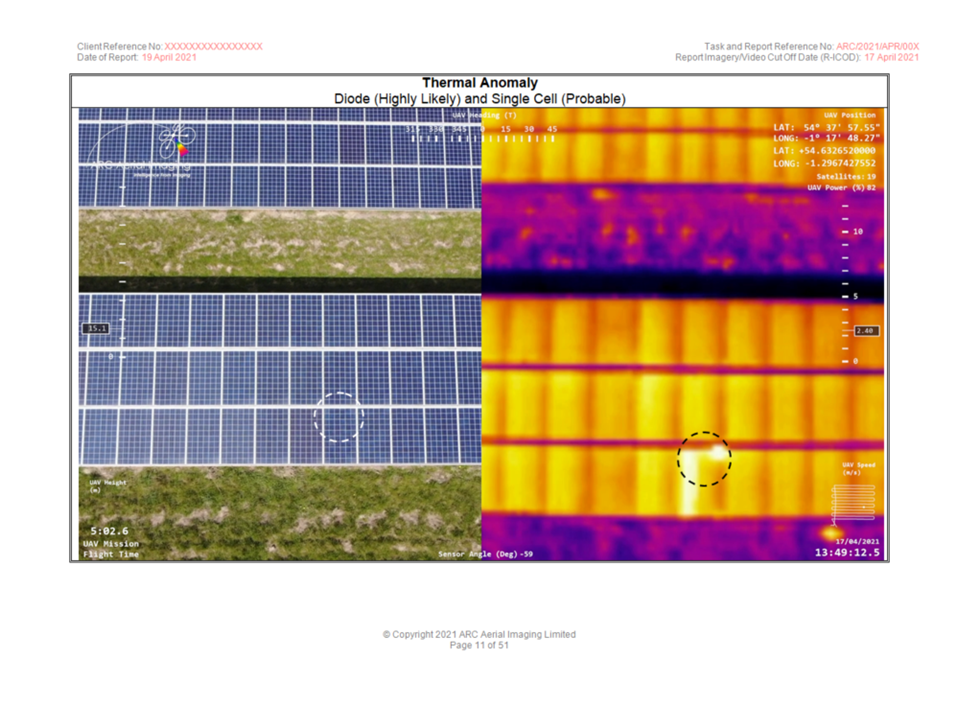

Can you spot the diode anomalies from this 30 second clip of a 20 minute thermal infrared photovoltaic solar array inspection undertaken with the capable Mavic 2 Enterprise Dual UAV?

Even with a relatively small IR sensor, valuable thermal infrared videos can still be gained to understand potential issues of arrays including small in size single cell and diode anomalies.

Furthermore and immediately post UAV flights, telemetry data can be overlaid on to both captured RGB and IR videos to create informative and referenced outputs.

Single cell anomaly detected.

Single cell anomalies with temperature recorded at 29 degrees Celsius from a normal temperature of 17 degrees Celsius.

Diode anomalies with temperatures recorded at 27 degrees Celsius. The normal array temperatures were recorded at 17 degrees.

We can produce an ‘Imagery Analysis and Inspection Report’ to accompany high resolution inspection videos that have post-flight UAV telemetry data overlaid to comparison split-screen videos to provide useful communicative and referencing information towards the client’s documentation uses and for the onward rectifications of those detected issues.